Greensane actief koolfilter

Greensane heeft een innovatief actief koolfilter ontwikkeld met actief koolstof om schadelijke stoffen af te vangen.

Reduceer emissie aanzienlijk met een actief koolfilter

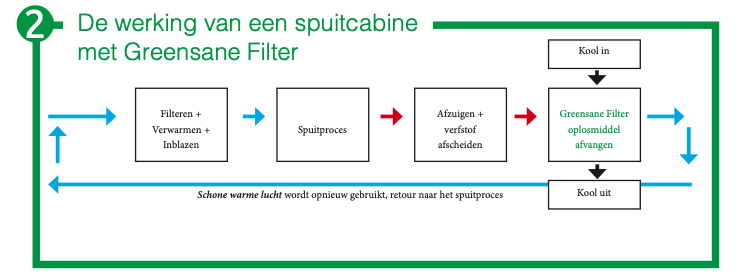

De innovatieve techniek achter het Greensane Filter maakt het mogelijk om de uitstoot van uw bedrijf aanzienlijk terug te brengen.

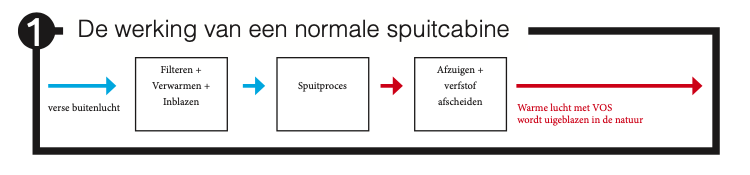

Een normale afzuiginstallatie stoot warme lucht met Vluchtige Organische Stoffen (VOS) uit. Vanwege de groeiende emissieproblematiek, en het strenger naleven van het Uitstootplafond, is het belangrijk dat bedrijven flink minder VOS gaan uitstoten. Dit geld eveneens voor NH3 en CO2 uitstoot.

Actief koolfilter

Het is bewezen dat koolstof filters uitermate geschikt zijn om VOS (cq giftige gassen) af te vangen. Door de scheikundige reactie van VOS (cq giftige gassen) met kool worden alle vervuilde delen in het filter opgevangen, en gaat er alleen nog schone lucht naar buiten.

Greensane heeft het concept van het koolfilter compleet doorontwikkeld zodat alle VOS (cq giftige gassen) emissie wordt opgevangen binnen uw vergunning. Het gepatenteerde systeem van Greensane zorgt ervoor dat al het oplosmiddel uit de warme lucht wordt gefilterd. Daardoor stoot uw afzuiginstallatie niet langer VOS (cq giftige gassen) buiten uw vergunning uit de lucht in. Dat is belangrijk voor het milieu, maar is ook steeds belangrijker om met uw bedrijf te blijven voldoen aan de strenger wordende maatregelen, want GREENSANE stuurt uw uitstoot.

Kies voor duurzaamheid en besparing

Schadelijke stoffen

Spuiterijen en andere schadelijke stoffen verwerkende organisaties zijn een grote oorzaak van het overschot van emissie in Nederland.

Regelgeving

Er wordt steeds strenger opgetreden tegen spuiterijen en andere organisaties die te veel uitstoten.

Voorkomen is beter

Grijp op tijd in en voorkom dat uw bedrijf gedupeerd wordt door opgelegde boetes.

Nieuwsgierig naar onze oplossingen?

Plan een afspraak en kom langs.

Bespaar op gasverbruik

Het Greensane Filter zorgt er niet alleen voor dat VOS niet langer uitgestoten worden. Een ander groot voordeel is dat warme lucht opnieuw wordt gebruikt!

Elke spuitcabine heeft warme lucht nodig. De temperatuur in de cabine moet warm genoeg zijn en blijven om goede kwaliteit van het spuitwerk te waarborgen. Het verwarmen van lucht kost natuurlijk heel veel gas, een grote kostenpost!

Hergebruik warme lucht

Maar waar normale oplossingen alle (vervuilde) warme lucht uitstoten, zorgt het Greensane Filter ervoor dat alléén het oplosmidel wordt afgevangen, en dat de warme lucht bewaard blijft en opnieuw het systeem in wordt geblazen. Daarmee wordt enorm veel gas (en dus geld) bespaard!

Onze andere producten

Onze baanbrekende technologie helpt u om uw uitstoot te verminderen én te besparen op uw energiekosten.

Koolstof resourcing

Greensane heeft de specialistische kennis in huis om voor ieder soort oplosmiddel de juiste soort koolstof te vinden om de Vluchtige Organische Stoffen (VOS) goed af te vangen.

Energie Investerings Aftrek

Wij helpen u graag met besparen. Zowel op brandstof als op stookkosten kunt u tot enorm veel geld besparen met de oplossingen van Greensane.

Contact met GreenSane

Contact

Greensane B.V.

Gezellenstraat 18

3861 RD Nijkerk

Nederland